Hot tub IN CUP LUX 200 rotomolded, integrated heater

Hot tub IN CUP LUX 200 rotomolded, integrated heater

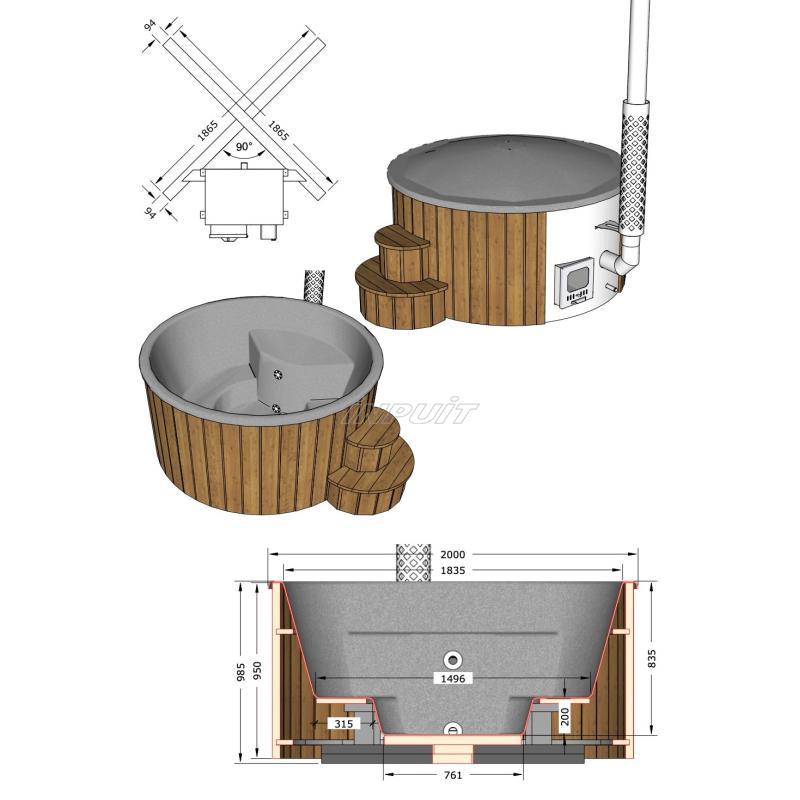

- hot tub measurements: L 2000 mm (external)/1835 mm (internal) x S 835 mm x H 985 mm

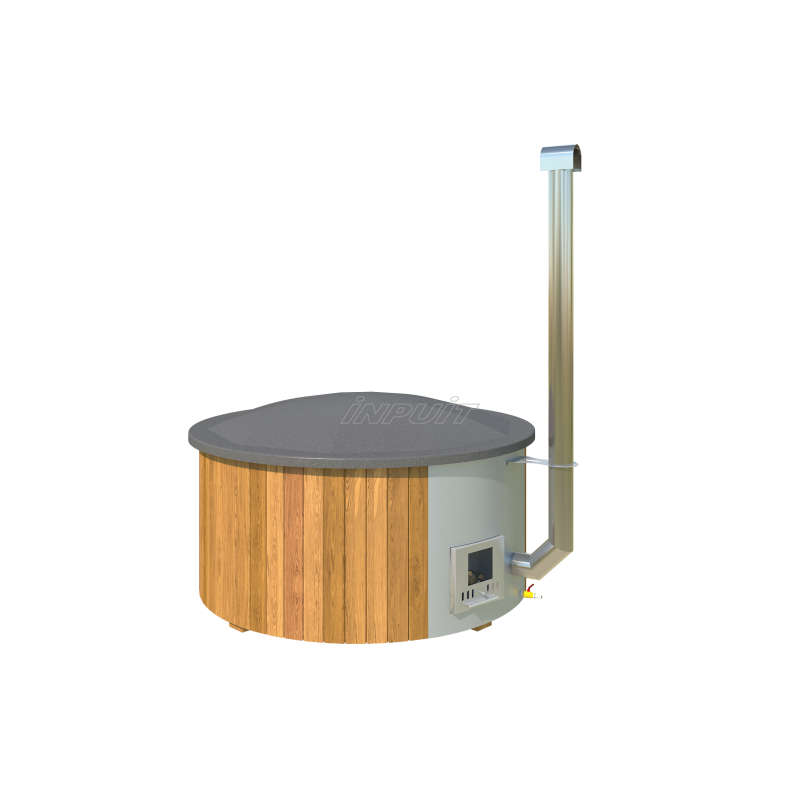

- material: thermowood

- rotomolded color: marble/grey

- thermowood color: brown (painted)

- rotomolded hot tub cover: marble/grey (included)

- heating time: 1,5-2 h

- 3 mm internal heater

- power: 35 kw

- hot tub chimney 2000 mm

- chimney safety cover (included)

- extra (extension) chimney (not included)

- wooden steps (included)

- drain (included)

- capacity: 1100 l

- people: 4-6

- package measurements: L 1150 mm x S 2100 mm x H 2150 mm

- weight: 250 kg

Options (not included):

- water purifying system

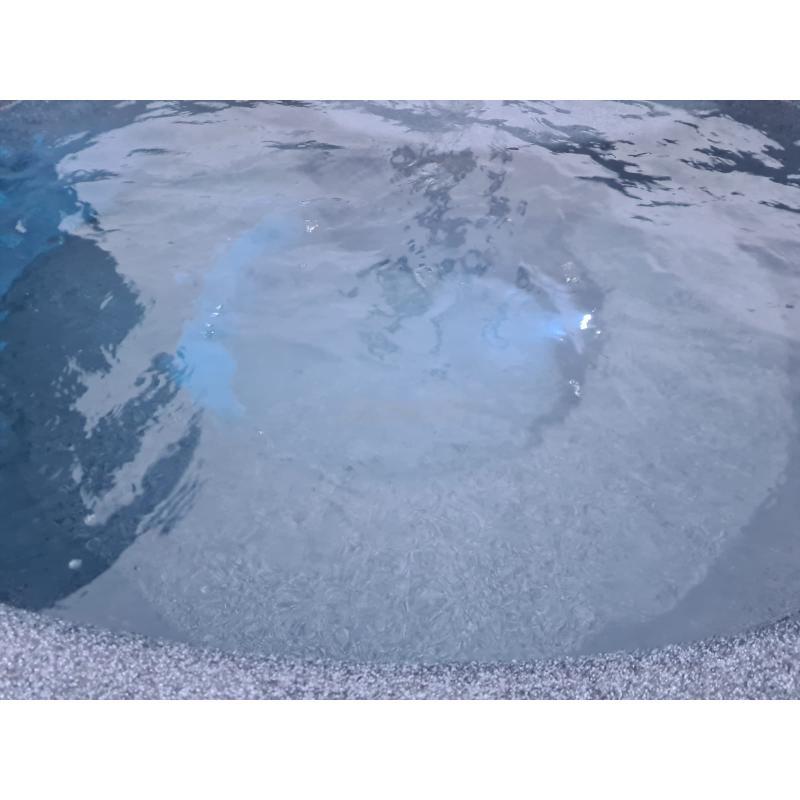

- led lighting: with one or multicolor

- filter system (with wooden steps)

The benefits of rotomolding:

- the product has been cast in one piece, therefore, the risk of it developing cracks and leaks has been minimized;

- the materials have excellent chemical resistance and are reusable;

- the materials can be used within a wide temperature range;

- the products are non-corrosive; the products are more environment-friendly.

For years, hot tubs have been made of glass fibre. The latter may be harmless for the person enjoying the pleasures of the tub, but the same cannot be said regarding the manufacturers and the environment. The chemicals used in the process of producing glass fibre create toxic compounds that are emitted into the air and then inhaled by the manufacturers as well as dispersed into the surrounding environment. Everyone who has ever been in close contact with the process or lived near a place where glass fibre has been produced can undoubtedly recognize the smell that is far from pleasant. For producing the hot tubs of the new IN CUPELLA series, we use an alternative technology, where the production process is safe for both the production crew and the environment. The look stays the same, as it is visually difficult to tell a hot tub interior made of rotational plastic apart from that made of glass fibre.